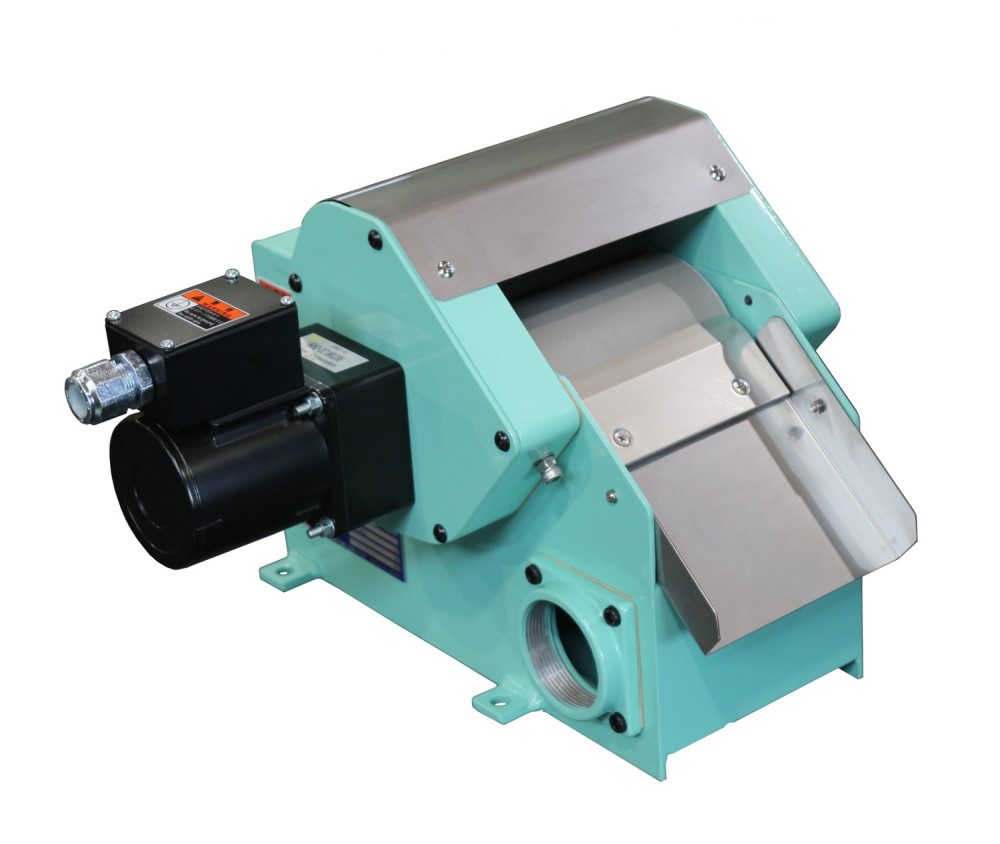

MS-4FC

(SERTEC motor)

[Application]

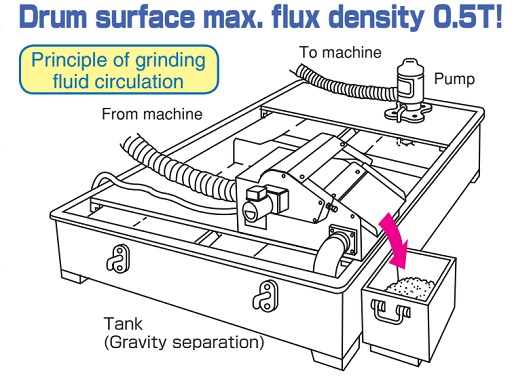

This is unti is incorporated in the coolant purification and circulation system for grinders to remove iron particles, a major part of purification.

When it is used together with a tank in which particles other than iron powder such as abrasive grains are separated by floating and precipitation,

re-precioitation, repurified and regenerated coolant can be supplied to grinders agein.

[Features]

- The construction of a stationary magnet and a rotary outer drum shell has no magnet in the area of the rake plate and allows smooth discharge of sludge.(The life of the rake plate is also prolondged.)

- The magnetic drum rotation drive construction has been modified to improve surability significantly.

- The squeezing roller tensioning mechanism has been designed anew to improve the squeezing performance.

- The squeezing roller and inlet are convered to enhance asfety as well as to pervent grinding coolant from splashing/scattering.

- The outlet can be located on the right,left or bottom thanks to a good criculation system layout.

- The high magnetic force MAGCLEAN (MS-FH・MS-FHP:rare earth magnet) works effociently for collecting weak magnetic sludge and minute slude.

- A Type having a motor on the right side(MS-F-R) is also available.

Precautions for use

Precautions for use

This is dedicated to grinding fluid(water soluble) only. If you plan to use the Magclean under the following conditions or if you cannot decide a suitable model, please fill the Magclean inquiry sheet at the end this catalog and consult with us in advance.

- Grinding fluid is oil based.

- Liguid other than griding fluid is used

(such as fresh water and chemical liquid). - The squeezing roller forced drive type is used.

- KANETEC MS-D type is to be updated.

- Liquid to use is not at normal temperature.

You can watch video introsucing MAGCLEAN.

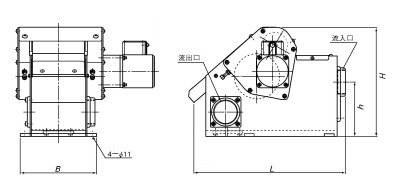

MS-FC/FCH/FCHP

MS-FC-R

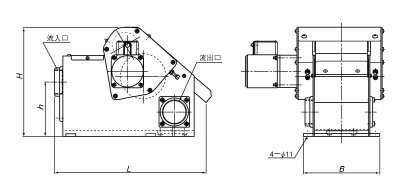

| 【Specifications】 | (mm) | ||||||||||

| Model | Processing Capacity |

Power Source |

Motor | Dimension | Mass | ||||||

| Standerd Type | High magnetic force type | Super High magnetic force type | Moter on the Right Side | B | L | H | h | ||||

| MS-2FC | MS-2FCH | MS-2FCHP | MS-2FC-R | 20L/min | 3-phse Ac200/220V 50/60Hz |

25W | 141 | 375 | 271 | 135 | 15kg |

| MS-4FC | MS-4FCH | MS-4FCHP | MS-4FC-R | 40L/min | 191 | 380 | 18kg | ||||

| MS-6FC | MS-6FCH | MS-6FCHP | MS-6FC-R | 60L/min | 241 | 21kg | |||||

| MS-8FC | MS-8FCH | MS-8FCHP | MS-8FC-R | 80L/min | 40W | 341 | 510 | 286 | 142 | 32kg | |

| MS-12FC | MS-12FCH | MS-12FCHP | MS-12FC-R | 120L/min | 441 | 515 | 151 | 38kg | |||

| MS-18FC | MS-18FCH | MS-18FCHP | MS-18FC-R | 180L/min | 491 | 655 | 321 | 165 | 45kg | ||

| MS-24FC | MS-24FCH | MS-24FCHP | MS-24FC-R | 240L/min | 541 | 50kg | |||||

| *All models come with a sludge bock | |||||||||||

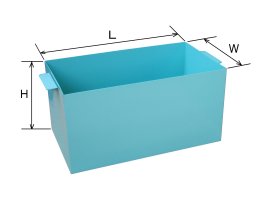

Sludge box:MS-2F*/4F*/6F*

| Model | Dimensions (mm) | ||

| L | W | H | |

| MS-2F* | 193 | 148 | 82 |

| MS-4F* | 267 | 165 | 95 |

| MS-6F* | |||

Sludge box:MS-8F*/12F*/18F*/24F*

| Model | Dimensions (mm) | ||

| L | W | H | |

| MS-8F* | 308 | 170 | 210 |

| MS-12F* | 410 | 230 | |

| MS-18F* | 460 | ||

| MS-24F* | 510 | ||

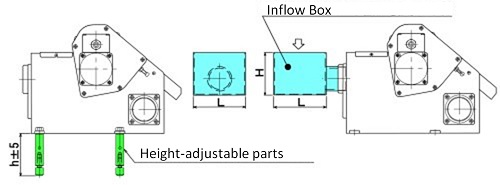

Optional components to support MS-F installation

Inflow Box

Height-adjustable parts

Inflow Box

Height-adjustable parts

| Model | Dimensions (mm) | ||||

| Standard Type | High magnetic force type | Super High magnetic force type | h | L | H |

| MS-2FC | MS-2FCH | MS-2FCHP | 105 | 110 | 105 |

| MS-4FC | MS-4FCH | MS-4FCHP | 130 | ||

| MS-6FC | MS-6FCH | MS-6FCHP | 150 | ||

| MS-8FC | MS-8FCH | MS-8FCHP | 155 | 170 | 115 |

| MS-12FC | MS-12FCH | MS-12FCHP | 190 | ||

| Machine tools and Equipment |

Iron Powder(Sludge) and Chips |

Magclean | Chip Magclean |

Paper Filter after Treatment by Magclean |

Magclean after Separeation and Collection by Chip Conveyor |

(Ref.) Chip Conveyor |

| Precision grindfing machine Honing machine |

Sludge Fine iron powder |

△ | ☓ | △*1 | - | ☓ |

| Cylindrical grinding machine Centerless grinding machine Surface grinding machine Rotary grinding machine |

Flocculent fine iron powder |

〇*3 | △ | 〇*1 *3 |

- | ☓ |

| Fine iron powder | 〇 | △ | 〇*1 | - | ☓ | |

| Machining center Milling machine LAthe Gear cutting machine Broaching machine Broaching machine Drilling machine Special machine |

Crushed chips End milling |

☓ | 〇 | ☓ | 〇*2 | 〇 |

| Special helical shape 60 mm or less |

☓ | ☓ | ☓ | 〇*2 | 〇 | |

| Cylindrical shape 60 mm or less |

☓ | ☓ | ☓ | 〇*2 | 〇 | |

| Tangled chips 60 mm or less |

☓ | ☓ | ☓ | 〇*2 | 〇 | |

| Washing machine | Fine iron powder about 100μm |

〇 | △ | 〇*1 | - | ☓ |

| Hardening equipment | Fine iron particles of various shapes |

△ | △ | △*1 | ☓ | ☓ |

△:Functions but collection rate and processing amount

expected to drop.

☓:Not suitable.

*2:Tow steps of chip collection and fine iron powder collection are possible.

*3:May not be collected by the standerd type. Please contact us.